Measures for food safety

All these measures can be broadly defined as “Self-control”, which is implemented through actions of a general and of a special type, enacted through general and particular actions, both systematically applied for the complete and constant control of production activities. “Measures of general nature” are represented by common rules that apply to all the work areas and are related to operator hygiene, premises, equipment, processes and products, as well as checking the applications of these rules. The purpose of these measures is to ensure the maintenance and control of the appropriate hygienic conditions of the operating personnel, processes, products, environments and equipment. The “Measures of a special kind” are defined for each type of production process and aim to identify, evaluate and control the specific dangers of a biological, chemical and physical nature, deemed as significant for the safety of food products. The dangers are evaluated according to standards set by the European legislation, other countries to which the products are destined, or by the WHO/FAO, generally known “Codex Alimentarius”.

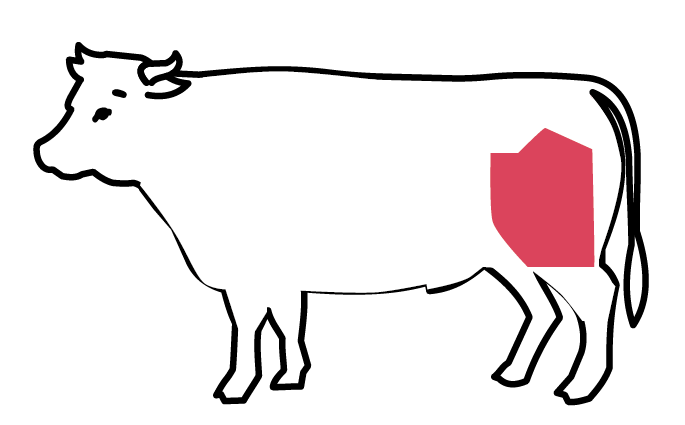

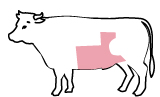

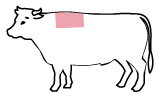

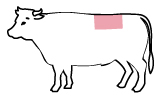

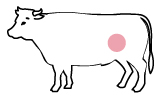

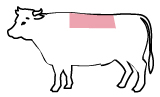

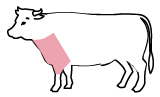

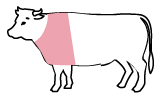

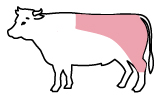

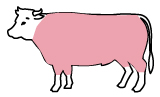

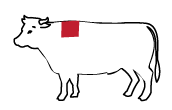

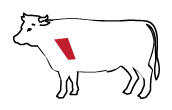

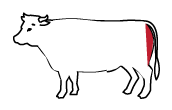

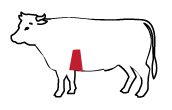

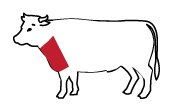

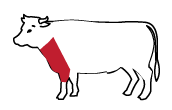

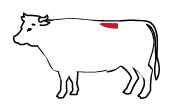

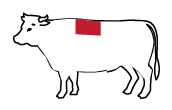

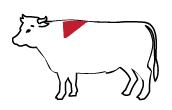

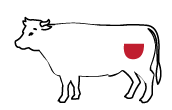

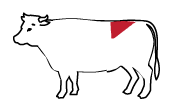

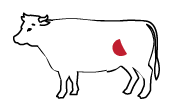

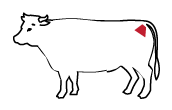

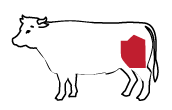

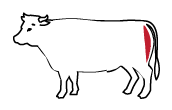

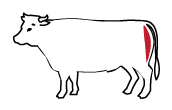

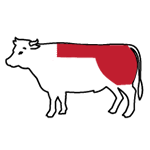

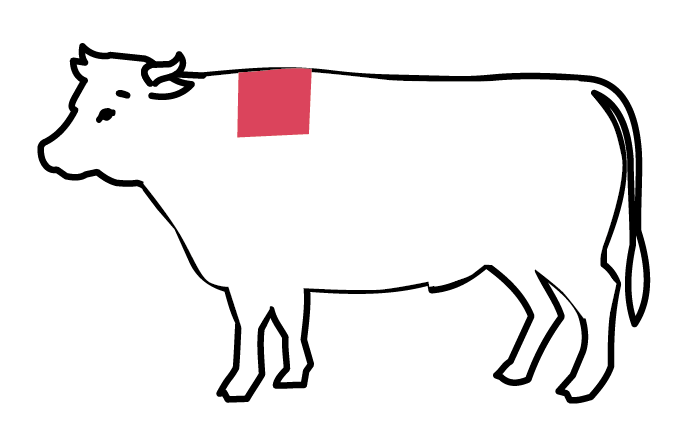

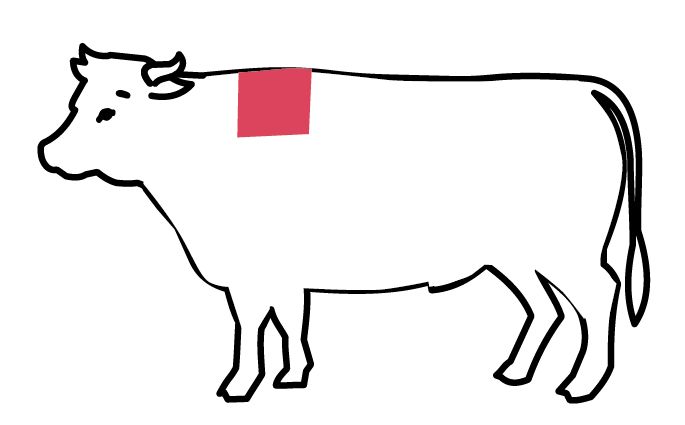

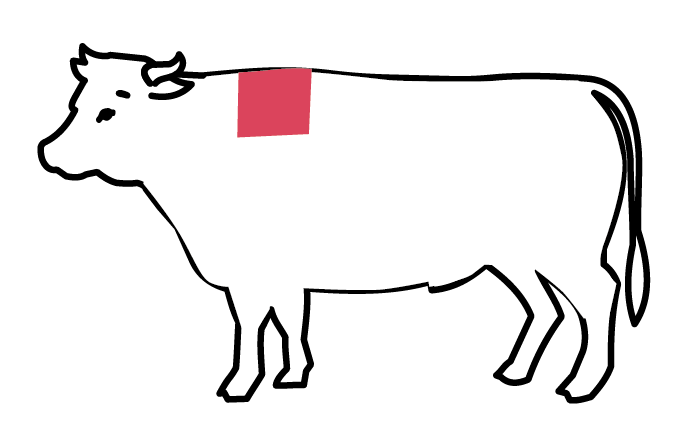

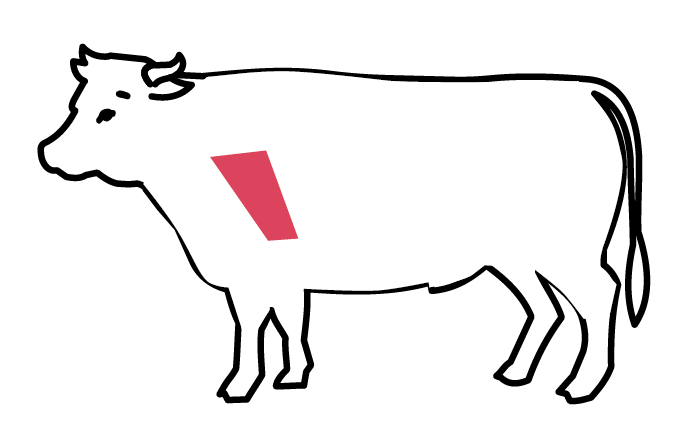

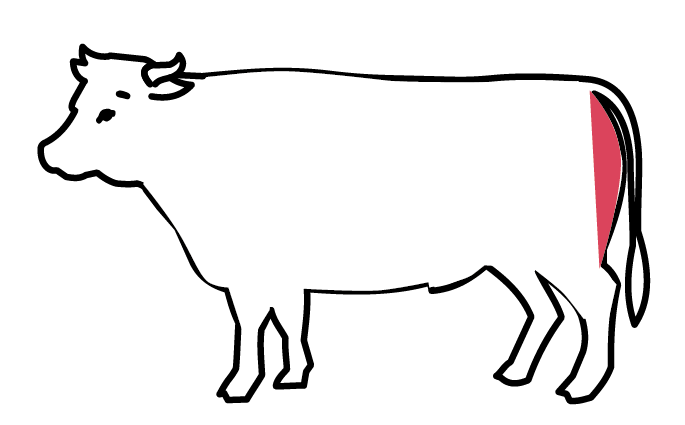

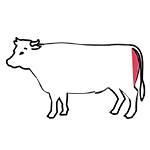

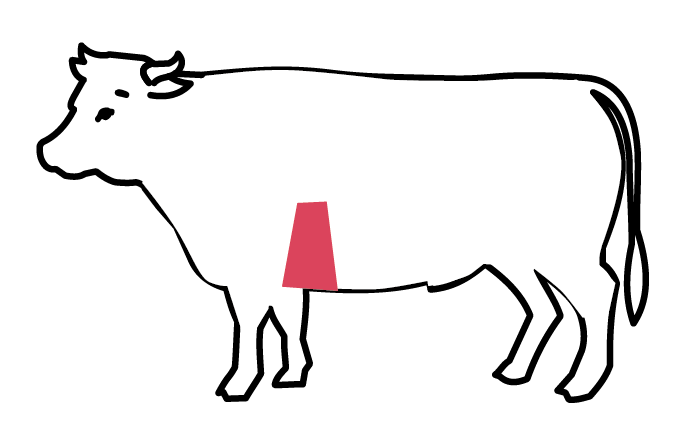

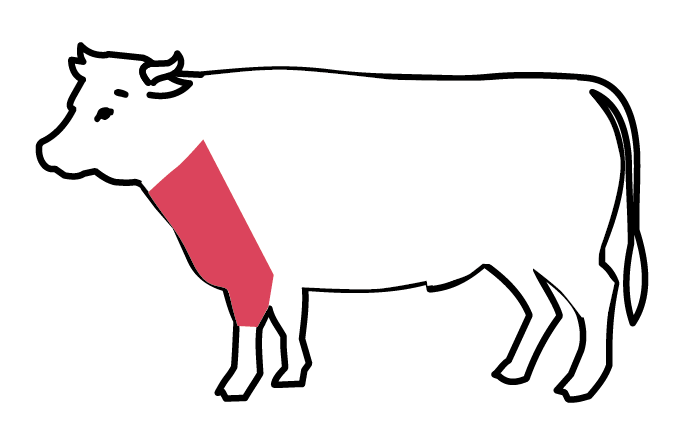

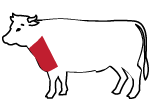

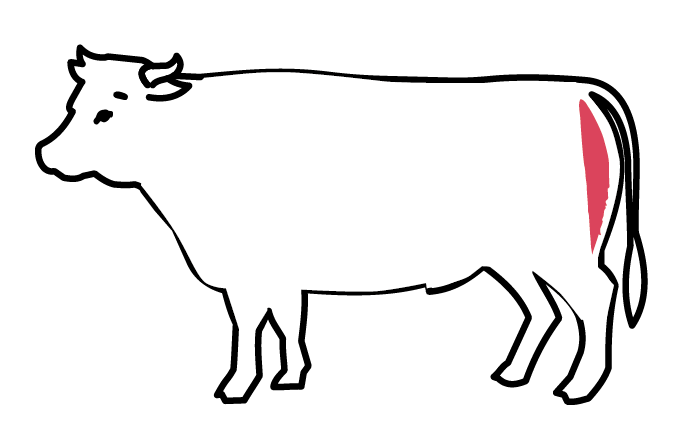

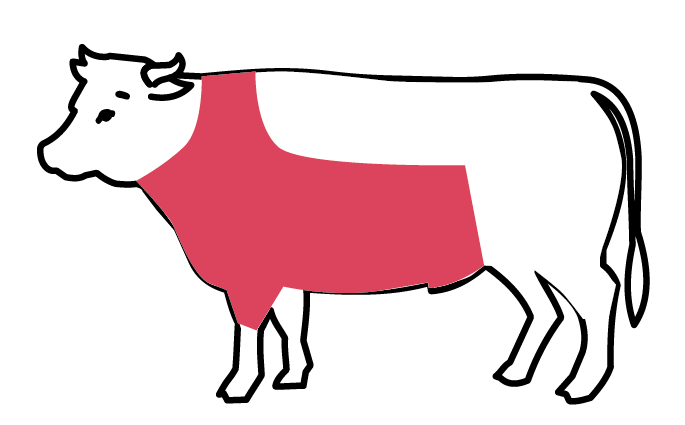

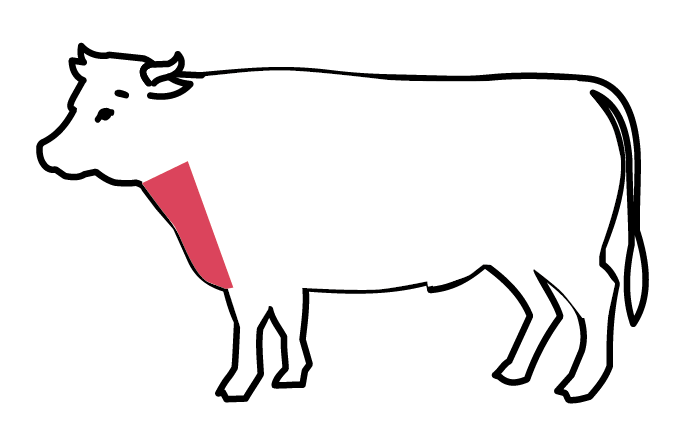

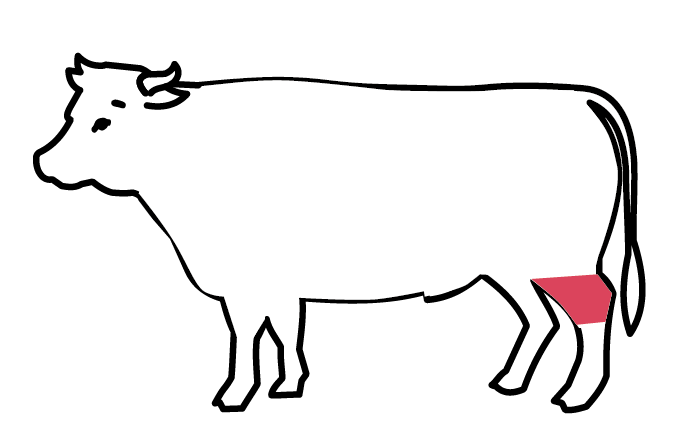

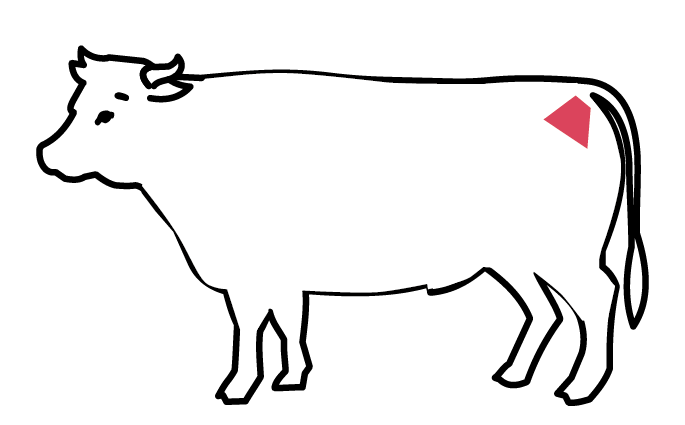

Identification and traceability of products

The overall system is thus based on the identification, within each work process, of the critical control points and provides the necessary actions to identify, eliminate or reduce to an acceptable level the significant threats to food security.

The control and accuracy of the information managed in the company system of identification and traceability of products constitutes a key element to support the effectiveness of any action implemented for quality, food safety and consumer communication.

As with all the elements of food security, also in the labelling field and consumer communications, INALCA undergoes external audits in order to verify the truthfulness, transparency and accessibility of all the information relating to products placed on the market.

Adoption of voluntary technical standards

The system implemented by INALCA for food quality and safety complies with the major international voluntary standards in this field, a common language adopted at international level which, on the basis of independent controls, confirms the effectiveness of the actions enacted by INALCA in this field.

The founding principles of quality policy

INALCA addresses the issue of food security through a system of rules and procedures whose purpose is to define, manage and control at all levels its standards of the supply chain. To ensure the technical adequacy of its control systems, INALCA promotes internally and throughout the supply chain the use of voluntary international technical standards.

Principle of centrality

An optimal level of food safety is considered a prerequisite for all farm products and is evaluated using methods of risk analysis.

Principle of demonstrability

All activities and business processes that can affect food security must be managed, monitored and documented, according to a defined hierarchy of references: rules and regulations, international technical standards, specific requisites of the companies using the products of the company.

Principle of governance

Specific figures and the system of governance of food security are clearly identified and formalised.

Principle of transparency

The information on food safety must be clear, comprehensible and accessible to Customers, Consumers and regulatory Authorities.

Principle of control

In the criteria of control the company uses internal auditing activities, external audits of client companies and, where applicable, audit certifications according to voluntary technical standards and independent international bodies.