Exclusively water of falda

For its production sites INALCA does not use water from surface sources, but only ground water, which offers greater guarantees in terms of quality. Over 90% of the water supply is also run directly by INALCA, both the extraction from the groundwater phase, and the phase of distribution, use, and purification. The integrated cycle managed entirely by INALCA ensures a “no waste” management of water resources because the distribution network is particularly guarded and controlled.

Furthermore the waste water presents a chemical and physical composition that makes it easily purified, thanks to the balanced relationship between the so-called Chemical oxygen demand (COD) and the Biological need of oxygen (BOD). Given the “food” nature of production processes, particularly hazardous substances to the environment, such as heavy metals, are not found in waste water.

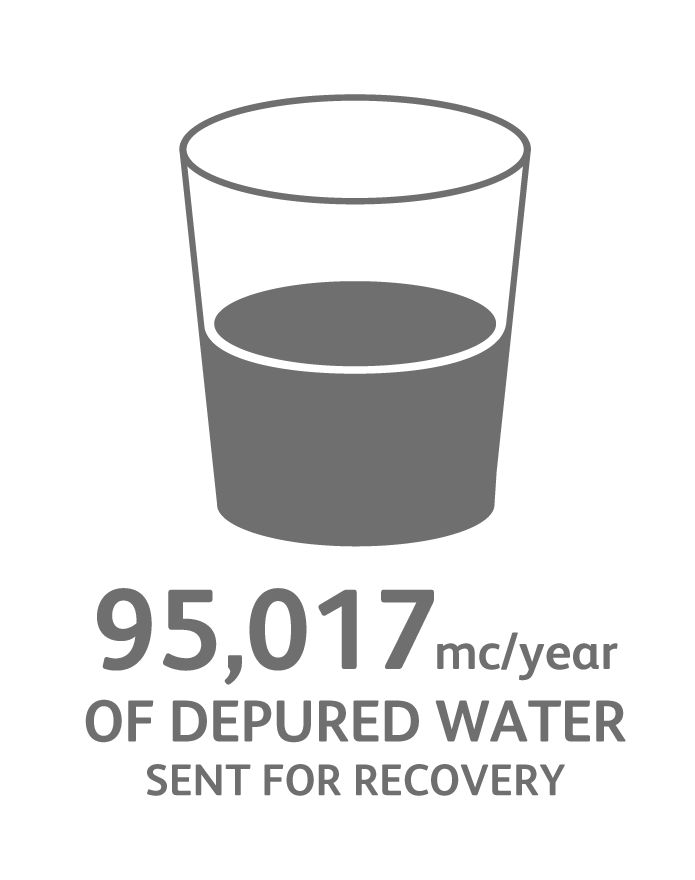

Modern depuration plants

The main INALCA plants are equipped with modern sewage plants that ensure a high purifying performance. For Castelvetro di Modena and Ospedaletto Lodigiano plants, INALCA has also been subject to more restrictive discharge limits than those foreseen by the plant’s environmental permit. In the Italian plant of Ospedaletto Lodigiano, the level of reduction has reached 50% of the authorised limit for the discharge COD parameter. When sector regulations allow, INALCA sends the water for purified process recovery. Over the last three years, INALCA has started to recover about 90,000 cubic meters of water per year. In 2020 the indicator was maintained and the company goal is to maintain these levels constant over time.