In tackling the issue of energy and energy efficiency, INALCA aims to provide its contribution to the fight against climate change, a global target identified by FAO for the period 2015-2030 and enshrined in major international agreements on the climate in Paris (COP21) signed by 195 countries. For more than 20 years INALCA has focused its efforts on energy efficiency; since 1997, in fact, the first methane cogeneration system was installed in the plant Castelvetro in Modena for the combined generation of electricity and heat.

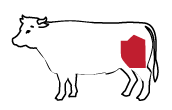

6 million euros

invested in the plant

of anaerobic digestion

For INALCA, 2016 is a turning point in the fight against climate change. As part of the acquisition of the UNIPEG ASSOFOOD Group, INALCA has acquired an additional anaerobic digestion facility at the Pegognaga (Mn) plant and above all its participation in a 5 MW for the combined production of heat and electricity, in addition to the needs of the adjacent Pegognaga plant; this plant is owned by UNITEA S.r.l., owned by INALCA at 50%, and is fully fuelled with renewable sources, in particular animal fats.

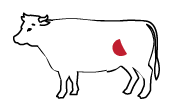

97% of energy

self-produced by biomass and cogeneration

The contribution of this plant to environmental sustainability is extremely important: it will in fact increase the share of self-produced energy to almost 98% of its needs (equivalent to 105,367 MWh), but above all to drastically improve its percentage of renewable sources which ranges from about 5% to 40% of its requirements (43, 157 MWh).

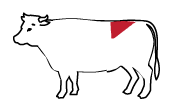

17.000 tons of biomass

trasformed into

47.734 MWh of energy green

Cogeneration and biogas are a winning conjunction, rewarded by the national incentive system. Through this plant network, in 2017, the Group obtained incentives (former green certificates) covering the total of biomass energy produced by biomass equal to 70,500 regarding the cited UNITEA plant and the INALCA biogas plant of Ospedaletto Lodigiano to which 4,097 white titles (EET) must be added concerning the cogeneration facilities installed at the Castelvetro (MO) plant. These incentives represent the national instrument for supporting energy efficiency and renewable energy production.

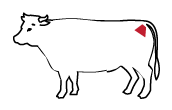

-22,244 tonnes/year

of Co2 saved

For about 10 years, the Group has been promoting and implementing energy efficiency projects at the main production facilities. Thanks to these interventions, in the five-year period from 2013 to 2017, the INALCA Group obtained approximately 42,000 Energy Efficiency Titles (EET), saving energy for one equivalent of 50,000 TOE (Tons of equivalent oil), corresponding to around 2,100,000 GJ. In 2017, savings in terms of CO2 not emitted amounted to 36,800 tons of CO2, slightly higher than 2016.